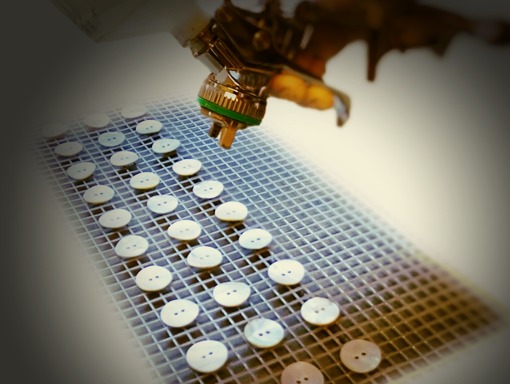

Varnishing

Protection and finishing of buttonsThe company Anker-Knopf works with the paintwork with a very elaborate procedure, which achieves the best possible results. The buttons are laid by hand on a grid, varnished on the front, dried in a heating oven, turned over by hand, varnished on the back and dried again in a heating oven. There are two reasons to paint buttons:

- Protective coating: The protective coating – also called zaponation – usually takes place on surface-colored buttons, if they are to be processed with contrast.

- Effect painting: The effect painting is an optical refinement of the button surface. Our many years of experience in our own paint shop ensures fast and customized results.